Company Overview

Bell Aliant Centre – University of Prince Edward Island Campus

Formerly Capital Area Recreation Inc (CARI), the Bell Aliant Centre is Charlottetown and the surrounding area’s most comprehensive athletics facility. Covering 160,000 square feet, this building houses an aquatics facility, two ice surfaces, and also provides space for other community and industry organizations

Problem Statement and Purpose of Design

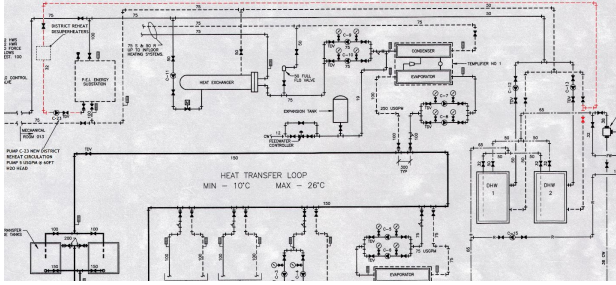

Bell Aliant’s current system works with three loops, a Heat Transfer Loop (HTL), Heat Recovery Loop (HRL) and an Ammonia Loop. The heat would start in the Ammonia Loop via rink compressors and travel into the Shell & Tube as well as the Plate & Frame.

The problem to solve is to re-purpose the existing desuperheaters (water heaters powered by the hot ammonia refrigerant) for Rink B to reheat the building’s heating water, which is normally heated by district heat, and consequently reduce district heat usage.

Heat exchanger

Diffuser

Video of Bell Aliant Centre tour of existing desuperheaters

Design Solution

The solution proposed is to repurpose the Rink B desuperheaters to re-heat a branch of the heating-water return (HWR) line. When Rink B’s refrigeration plant is running, the HWR water temperature entering the District Heat Exchanger will be increased, and it will require less metered heat to bring it back to heating-water supply (HWS) temperature. Consequently, Bell Aliant Centre’s energy bill for district heat will be less, having recycled heat within the building.

Valve and Gauges Changes

Rink B System Desuperheater Schematic (Pipe Only)

The Above drawing shows three changes in the mechanical drawings of the system: ie. A 50mm x 32mm TEE, 32mm steel piping of approximately 15ft and one elbow. When Rink B’s refrigeration plant is running, the HWR water temperature entering the District Heat Exchanger will be increased, and it will require less metered steam to heat it back to HWS temperature.

Rink Froid and Client Bell Aliant Centre

Implementation Plan

The implementation of the final design will first start in the templifier room. The valve connecting the snowmelt pit to the Heating Water Supply (HWS) closest to the HWS must first be closed to inhibit flow to the line, then the Triple Duty Valve (TDV) must also be closed to isolate the line that contains pump C-16.

Sustainability

Materials will be Reused. Although some new machinery is required, it’s a small

environmental investment compared to the equipment which is existing and will be reused.

Conclusion

Early on in the project, time was devoted to understanding the Client’s systems from a heat-recovery perspective, and exploring the possibilities for using available heat within the facility. Concepts were developed and compared, leaving desuperheater repurposing as the proposed solution.

The solution was prototyped using a simulation model, which was based on testing of the existing Rink A desuperheaters. When the simulation was complete it was found that the solution would save Bell Aliant Centre about $2027 per year in energy.

The result is a proposal with a low capital cost, a short payback period, and a straightforward approach to moving excess heat back into the building mechanical systems, which can be recommended for implementation.