Project Background

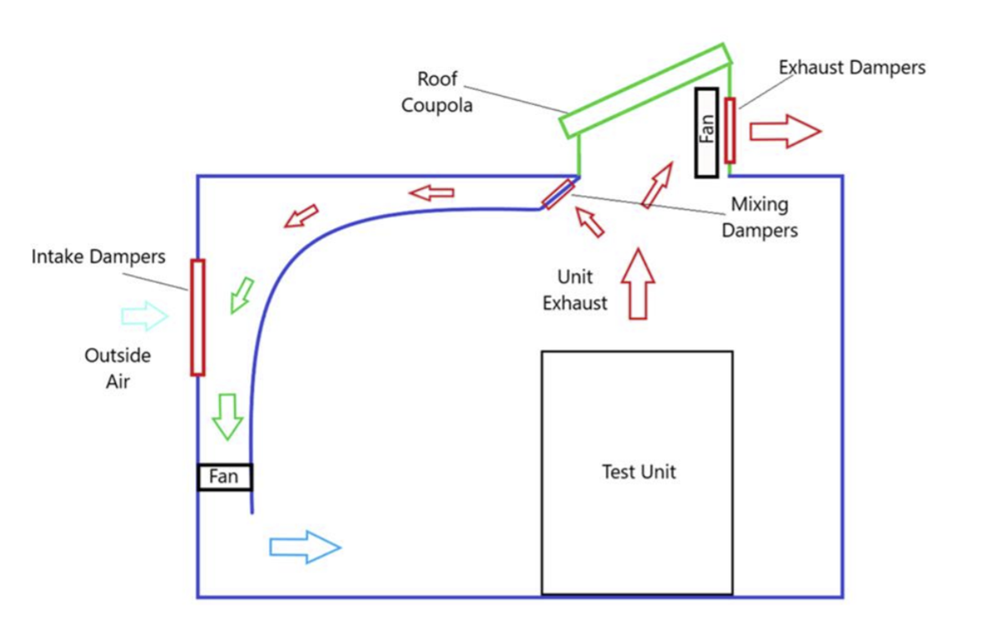

Baltimore Aircoil Company (BAC) manufactures cooling towers, which they test within a lab at their facility in Jessup, Maryland. To generate the most accurate and useful results, they wish to maintain a constant wet bulb temperature within the lab during a test. However, as the test is run, the cooling tower emits large amounts of warm humid air, which accumulates within the lab and creates an ever-changing wet bulb temperature. Currently, technicians are tasked with manually controlling two sets of fans, and three sets of dampers to manage the lab environment.

Problem Statement

“Design an Automated Airflow Management System Capable of Maintaining a Set Wet Bulb Temperature Within a Thermal Lab.”

Requirements

1 – Maintain a wet bulb temperature at +/- 1 °F from the setpoint.

2 – Design must deliver consistent lab environments between 60 °F and 82 °F wet bulb temperature.

3 – Design must function for a 39’ 4” W x 67’ 4” L x 34’ H lab but be scalable for different size labs.

4 – Design must be suitable for all sizes of testing units, from 4’ x 3’ to 14’ x 24’ in footprint.

5 – Design must control the following equipment by the stated inputs:

- 1x VFD for 2 Exhaust Fans: Eaton SVX9000 (0-10V and 4-20mA)

- 2x Mixing Fans: 15 Hp 3 Phase Electric Motors (No VFD)

- 6x Dampers: Belimo AFB24-SR motor (24VAC 0-10V)

- 6x Damper Position Controllers: SGA24sr (24VAC 0-10V)

6 – Design must be simulated to prove it is capable of meeting requirements prior to prototyping.