Throughout this project, the team had three major sections of the project beginning with investigating different problem areas, creating and installing a data acquisition system to acquire more information on the vacuum skid and finally developing a bearing fault detection system to indicate when a failure may be beginning to occur so the bearing failure is not a hard failure which results in extra costs for pump repair.

Problem Areas

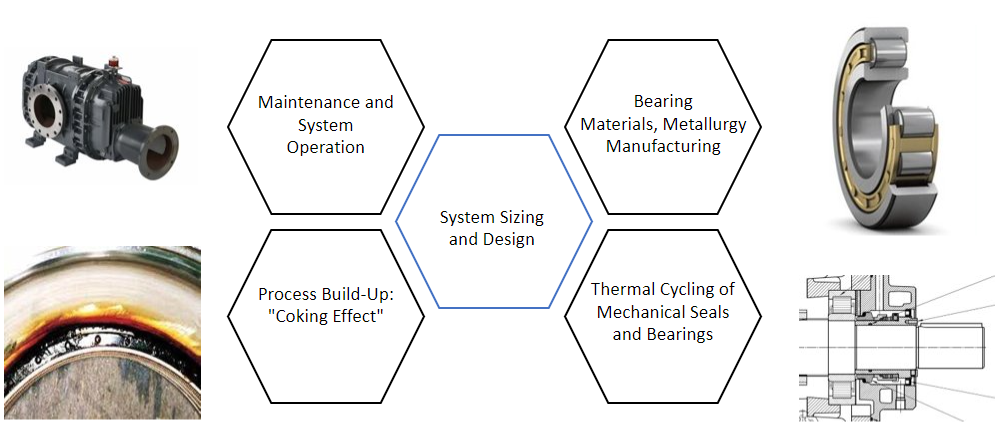

Due to the nature of the design project, the team’s conceptual design phase involved in depth research and investigation into the various problem areas which could be the cause of the HV8000 pumps’ early bearing failures. After our preliminary research, and through some discussions with Source Atlantic, the team identified specific problem areas which required further investigation. These areas were: bearing materials and metallurgy, system maintenance and operation, thermal cycling of the mechanical seals, system sizing and design and finally the ‘coking’ effect. Given the time constraints of the design project, the team agreed that only a select few of the problem areas would be able to be investigated. Compiling the team’s research in each of the area’s a ‘Failure Mode Effect Analysis’ was completed to access which of the problem areas were of most concern. Based on the results from this analysis, the team determined three problem areas which posed the most likelihood of being the leading causes of the premature bearing failures. The three areas being:

- Bearing materials and metallurgy

- System sizing and design

- System operation and maintenance

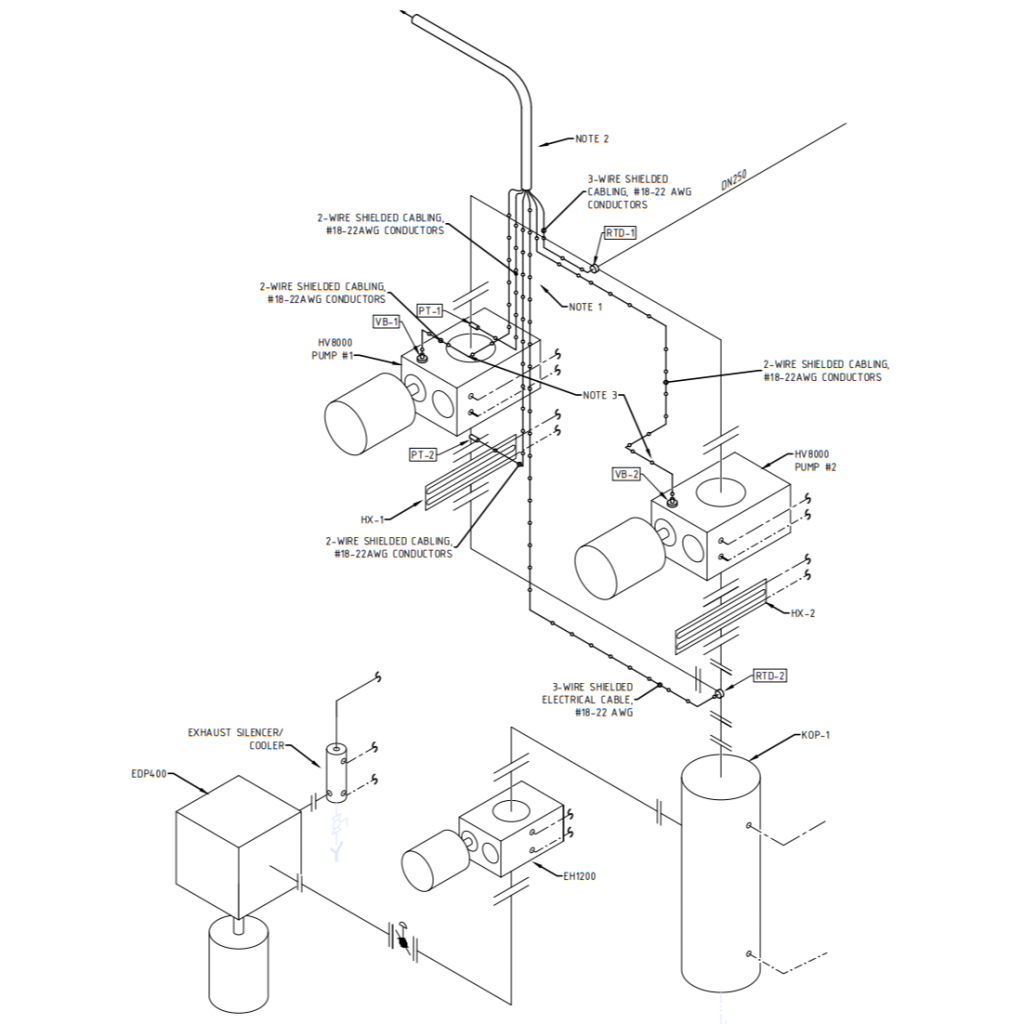

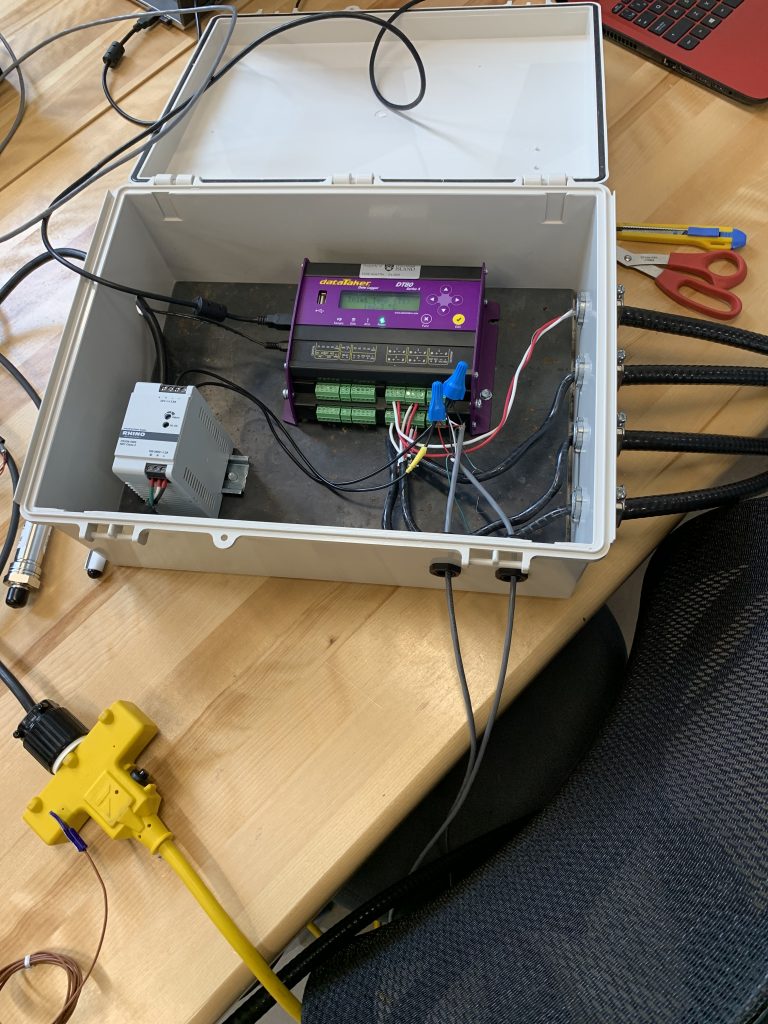

DAQ System

The team decided to move forward with a data acquisition system to acquire temperature and pressure readings from the vacuum skid to see if there were any discrepancies from the manufacturers specifications as there were no current data values. The results showed that there were no errors in the system and that everything was running to spec.

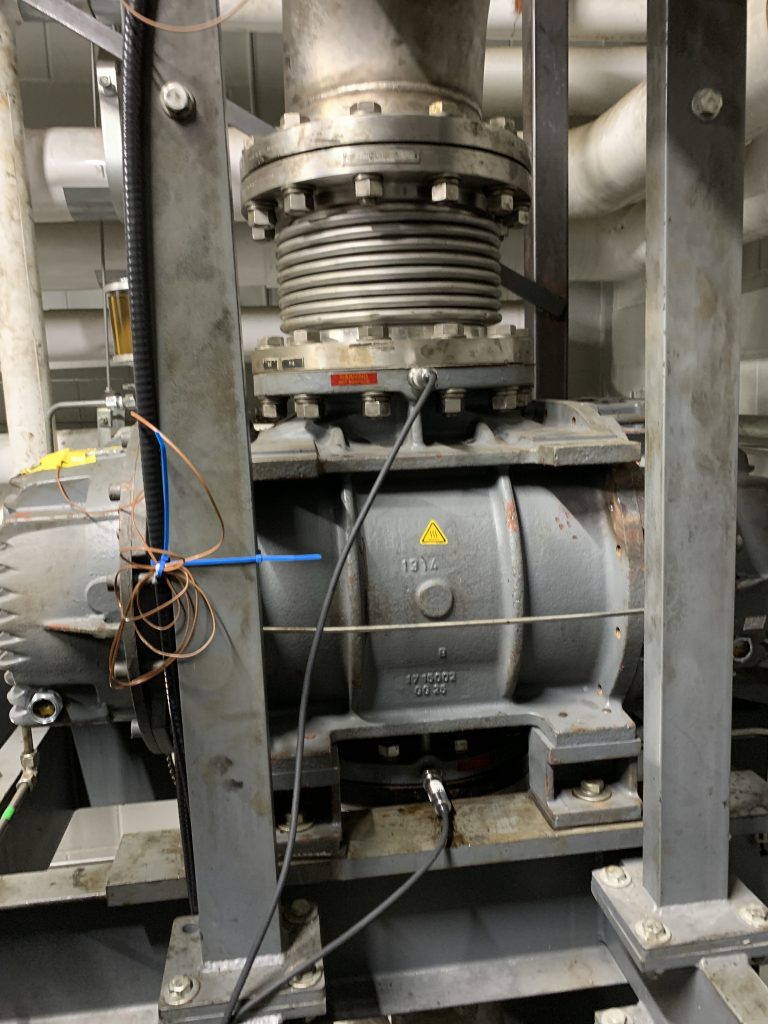

BFD System

Since there were no system discrepancies found using the data acquisition system, the team made the decision with moving forward with a system that will indicate when the bearings are beginning to fail via vibration sensors and a PLC with a human interface to communicate the warnings and values. This system will ultimately save cost for the client on pump repairs.