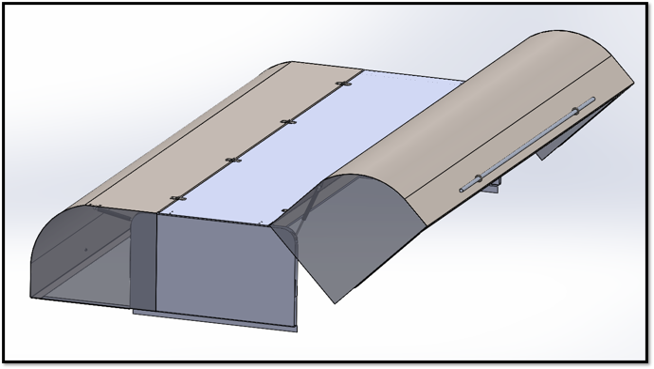

Final Design

Main Design Elements:

- Central C-Channel

- Rolled Door (x 2)

- Double Layered Side Panel ( x 2)

- Gas Spring (x 4)

- Spring Mounting Brackets (x 4)

- Strap Hinges (x 8)

- Lifting Bar (x 2)

The detailed design for the ADF6405T Cover consists of a central frame structure and a two-door system. The central frame contains two side panel components that are connected to a center channel, which spans the length of the cover.

The two cover doors are connected to the center frame via strap hinges. The use of four hinges for each door as well as the bolted assembly method ensures that the doors will be properly aligned and will not experience unwanted lateral motion. The lifting of the doors is supported by gas springs. These springs are mounted on the inside of the side panel as well as the underside of the doors. There are two springs on either end to allow for a smooth and even lifting. A lift bar is included for ease of use and to guarantee that the force required to open it is well distributed. Rivet nuts are used at all major connection points to improve the ease of assembly. This was also done to eliminate welded connections wherever possible. The elimination of large welds greatly reduces the risk of warping and ensures precise fitment.

Final Reccomendations

The team suggests that Atlantech Companies continue to develop this project by creating a full-scale build of the stainless steel central structure, using their usual manufacturers and suppliers. From here, it is recommended that the client continues to pursue a plastic door design, that better aligns with their interests. The plastic door design could be easily integrated with the existing metal central frame. Ultimately, the work provided by the student engineering team provides the basis for a full comparative analysis between the stainless steel and plastic door iterations, should Atlantech Companies feel it useful.