Company Overview

![]()

Atlantec BioEnergy Corporation is an ethanol production company involved in the distillation of fuel, pharmaceutical, and beverage grade alcohols. They extract sucrose used for the fermentation process from island-grown sugar beets.

Problem Statement

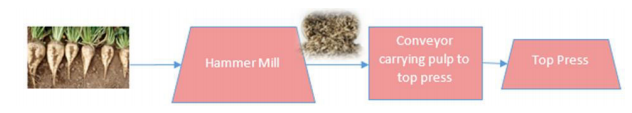

Atlantec Bioenergy Corporation truckes beets in from an off-site storage facility. The beets then enter a dirt tumbler, which removes dirt and debris. The tumbled beets then enter the hammer mill, which pulverizes the beets into a pulp. The pulp then enters the top press, where thin-juice is removed from the beet pulp. This step is repeated as the waste pulp is pressed again in the bottom press. The thin-juice from each press continues on to the fermentation stage, while the pressed pulp is removed as waste.

The Just Beet It project team were to try and find a design solution that would increase the amount of sugar extracted from beet pulp at the Atlantec Bioenergy Corporation facility.

Approximately 50% of the sugar is retained in the beet pulp waste. The School of Sustainable Design students were to solve and improve the efficiency of a sugar extraction problem for Atlantec Bioenergy Corportation beet processing plant.

Final Design

Various different designs were considered, with the spray conveyor being the chosen diffusion solutions.

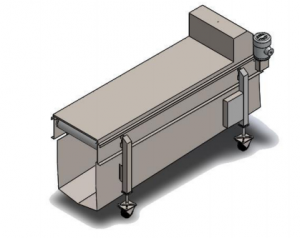

The spray conveyor is recommended as the final diffusion solution. The design increased the sucrose extraction rate of the sugar beet pulp by implementing heated water to diffuse into the beet pulp to degrade the cellular membrane and composition of the sugar beet cell structure.

Spray Conveyor

Beet cossettes are the standard for diffusion in the sugar beet processing industry, and are thin, v-shaped sliced of beets. Tests from the initial prototype showed that pulp consistently produced more sugar than a cossette-based extraction, as well as an overall increase in extraction efficiency from 50% to 65%. These tests also suggested that not mixing the water-beet mixture and using a smaller amount of water may also increase extraction efficiency.

Conclusion

The final solution has been designed to be retro-fitted onto the current Atlantec conveyor. This system would not disrupt the current layout of the Atlantec Facility. The water distribution system would be the only added infrastructure. This would require a 300Amp electrical panel with 4x40DP breakers, hooked up with 8 AWG wire. The water heater would then hook into the facility’s main water supply.

The economic impact of implementing the final design is determined using the results from the initial prototype with an improved extraction efficiency.